Curly Willow Wreath (Salix matsudana ‘Tortuosa’) for the Farmer Florist

Depicted in the art of ancient Greece and Rome, the wreath maintains its position as the classic floral design with high consumer appeal. This publication centers on wreath construction using corkscrew willow, often called curly willow in the florist trade, for sales to the public, florists, decorators, and other potential markets.

Production

Salix matsudana is native to northeastern China and is named in honor of Japanese botanist Sadahisa Matsuda. It gets its name from its unique branching habit. As the tree matures, horizontal branches begin to twist, creating the namesake corkscrews. Cultivars of corkscrew willow range in stem color from greenish to golden to orange-gold. Corkscrew willow is a fast-growing, small, deciduous tree, reaching a height of 25–30 feet with a 15-foot spread in USDA hardiness zones 4–8. Trees will thrive in part shade/part sun to full sun. These trees prefer moist soil and have aggressive root systems known to crack sidewalks and even break water lines. Take care to plant them far from homes and other structures.

S. matsudana is generally pest- and disease-resistant. Gypsy moths and aphids may be attracted to the tree, and powdery mildew and leaf spot may occur. Except for severe infestations, treatment or sprays are usually not recommended. However, the bark is thin and easily damaged from mechanical impact. Keep mowers and trimmers clear of the trunk.

Harvest and Handling

Corkscrew willow stems can last for years if handled properly. Cut stems may be stored in water at 34–36˚F for 6–10 weeks. Dry stems can be stored in boxes or plastic bags. Stems used in arrangements with water may begin to root and leaf out.

Design Construction

Many consumers like locally grown products and are often willing to pay the same amount for them as for products shipped from a distance. Producers of cut ornamental flowers and foliage can augment their sales with value-added products, including wreaths, during the fall and winter months when other crops are finished. Depending on the material and style, some wreath products are desirable year-round and should be manufactured regularly. This likeable characteristic is the case for corkscrew willow wreaths. This design is distinctive and appeals to consumers as a decorative indoor item.

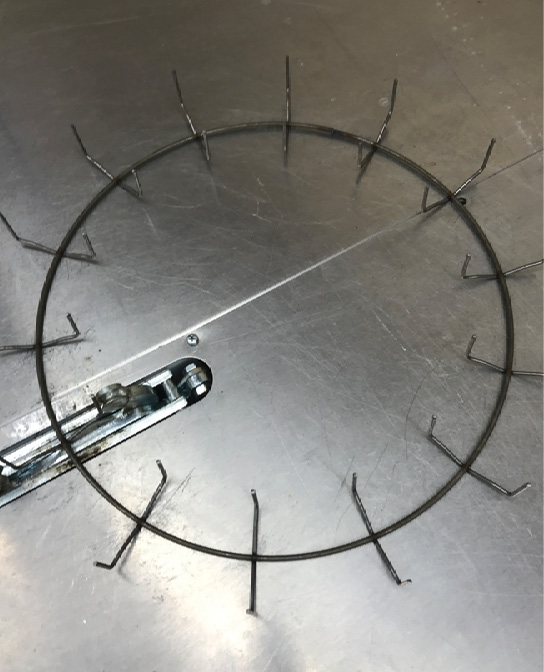

This wreath design uses defoliated tip growth of corkscrew willow in its fresh state, approximately 1.5 pounds, of lengths approximately 28 inches. The wreath is made on a 14-inch-diameter frame. The finished design has a 40-inch outside diameter.

All stems were manually defoliated to increase the visual appeal of the design and limit shedding. Manual removal is acceptable when making a few designs, but not for larger quantities. Willow leaves will fall in the winter, which naturally takes care of the problem, but it is possible to use hormonal defoliants. These increase leaf ethylene concentrations, leading to leaf drop.

Willow stem clusters are held in place and formed into a wreath shape using a wire, clamp wreath form, and associated clamp wreath machine. The wreath frame has wire prongs that receive loose bunches of plant material. The machine uses force to clamp the prongs around the bunch, holding it tightly in place. The clamping action is triggered by a foot pedal, leaving hands free to hold materials in place. Having the clamp mechanism permanently attached to a table is the best practice for commercial producers and a good choice for producers entering the wreathmaking marketplace.

Purchasing the materials to make this design from a wholesale florist would cost around $50. Our study found consumers are willing to pay much less than that figure, on average around $22.50. Still, if using willow grown on the farm, input costs are significantly lower, allowing you to sell this wreath and maintain a profit. For farmers who sell to florists, retailers can add value to the design through the addition of silk or dried flowers, increasing the wreath’s value and, accordingly, retail price.

Resources

Gilman, E. F., & Watson, G. G. (1994). Salix matsudana ‘Tortuosa’ corkscrew willow. Fact Sheet ST-577 Environmental Horticulture Department, Florida Cooperative Extension Service, Institute of Food and Agricultural Sciences, University of Florida.

Hudson, D., & Griffin, E. (2004). Market potential for “Mississippi grown” cut flowers. MAFES Bulletin 1140. http://www.mafes.msstate.edu

Posadas, B. C., & DelPrince, J. (2019). Consumer preferences and willingness to pay for wreath designs. Mississippi Agricultural and Forestry Experiment Station Bulletin, Mississippi State University. In press.

Sheerlund Products. Reading, PA. https://sheerlundproducts.com

Publication 3383 (POD-09-22)

By James DelPrince, PhD, Assistant Extension Professor, Ben Posadas, PhD, Associate Extension/Research Professor, and Christine Coker, PhD, Associate Extension/Research Professor, Coastal Research & Extension Center.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.